Top-down Prosthetic Heart Valve Fabrication Using Sheets of Tissue

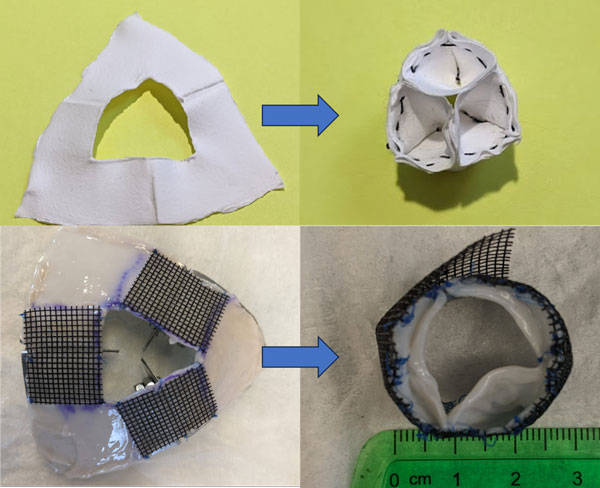

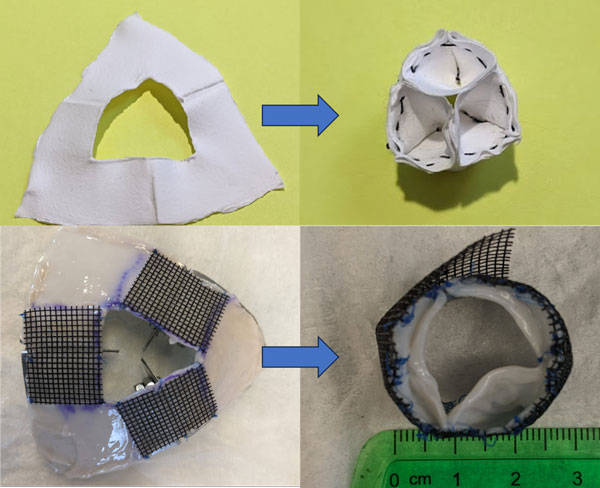

To develop self-healing prosthetic valves, many research designs use a bottom-up approach based around “growing” a valve using cells and scaffolding. Instead, CaRE's prosthetic heart valve fabrication technique uses a top-down approach. With inspiration from origami, we developed a novel 2-D template that folds into a functional 3-D valve and validated the design with sheets of polymer and preserved tissue.

To develop self-healing prosthetic valves, many research designs use a bottom-up approach based around “growing” a valve using cells and scaffolding. Instead, CaRE's prosthetic heart valve fabrication technique uses a top-down approach. With inspiration from origami, we developed a novel 2-D template that folds into a functional 3-D valve and validated the design with sheets of polymer and preserved tissue.

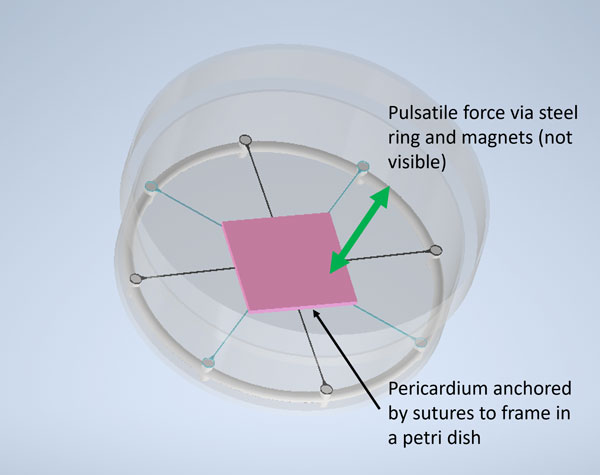

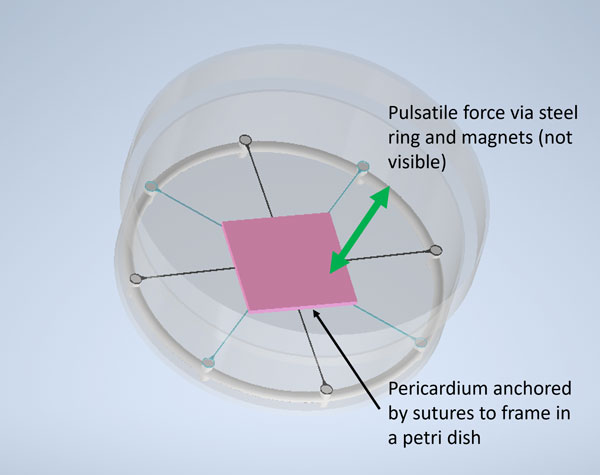

Currently, we are exploring methods to create the 2-D template with living tissues. We hypothesize that as the heart enlarges through the organism's natural life cycle, the surrounding pericardium undergoes increased tension. As the forces felt by pericardial mechanoreceptors increases, the tension stimulates secretion of local growth factors, causing the pericardium to grow in sync with the heart. This process ultimately relieves the initiating tension. CaRE is developing a method to mimic the motion of a growing heart in vitro to enlarge a sheet of living pericardium. Ultimately, CaRE hopes this technique can then be used to create the starting substrate for the folding method previously described or other valve assembly techniques.

Currently, we are exploring methods to create the 2-D template with living tissues. We hypothesize that as the heart enlarges through the organism's natural life cycle, the surrounding pericardium undergoes increased tension. As the forces felt by pericardial mechanoreceptors increases, the tension stimulates secretion of local growth factors, causing the pericardium to grow in sync with the heart. This process ultimately relieves the initiating tension. CaRE is developing a method to mimic the motion of a growing heart in vitro to enlarge a sheet of living pericardium. Ultimately, CaRE hopes this technique can then be used to create the starting substrate for the folding method previously described or other valve assembly techniques.

Investigators

William Yuan

William Yuan

Project Lead

Selected Publications

Tefft BJ, Choe JA, Young MD, Hennessy RS, Morse DW, Bouchard JA, Hedberg HJ, Consiglio JF, Dragomir-Daescu D, Simari RD, Lerman A. Cardiac Valve Bioreactor for Physiological Conditioning and Hydrodynamic Performance Assessment. Cardiovasc Eng Technol. 2019 03;10(1):80-94 PMID: 30311149 PMCID: PMC6541400 SCOPUS ID: 2-s2.0-85061993924 10/13/2018

Jana S, Tefft BJ, Spoon DB, Simari RD (2014). Scaffolds for tissue engineering of cardiac valves. Acta Biomaterialia, 10(7): 2877-2893. [PMID: 24675108]

Spoon DB, Tefft BJ, Lerman A, Simari RD (2013). Challenges of biological valve development. Interventional Cardiology, 5(3): 319-334.

View more CaRE Research

To develop self-healing prosthetic valves, many research designs use a bottom-up approach based around “growing” a valve using cells and scaffolding. Instead, CaRE's prosthetic heart valve fabrication technique uses a top-down approach. With inspiration from origami, we developed a novel 2-D template that folds into a functional 3-D valve and validated the design with sheets of polymer and preserved tissue.

To develop self-healing prosthetic valves, many research designs use a bottom-up approach based around “growing” a valve using cells and scaffolding. Instead, CaRE's prosthetic heart valve fabrication technique uses a top-down approach. With inspiration from origami, we developed a novel 2-D template that folds into a functional 3-D valve and validated the design with sheets of polymer and preserved tissue.  Currently, we are exploring methods to create the 2-D template with living tissues. We hypothesize that as the heart enlarges through the organism's natural life cycle, the surrounding pericardium undergoes increased tension. As the forces felt by pericardial mechanoreceptors increases, the tension stimulates secretion of local growth factors, causing the pericardium to grow in sync with the heart. This process ultimately relieves the initiating tension. CaRE is developing a method to mimic the motion of a growing heart in vitro to enlarge a sheet of living pericardium. Ultimately, CaRE hopes this technique can then be used to create the starting substrate for the folding method previously described or other valve assembly techniques.

Currently, we are exploring methods to create the 2-D template with living tissues. We hypothesize that as the heart enlarges through the organism's natural life cycle, the surrounding pericardium undergoes increased tension. As the forces felt by pericardial mechanoreceptors increases, the tension stimulates secretion of local growth factors, causing the pericardium to grow in sync with the heart. This process ultimately relieves the initiating tension. CaRE is developing a method to mimic the motion of a growing heart in vitro to enlarge a sheet of living pericardium. Ultimately, CaRE hopes this technique can then be used to create the starting substrate for the folding method previously described or other valve assembly techniques.

William Yuan

William Yuan